Damage Caused By Poor Venting

Poor Venting

Failed shingles, caused by no soffit venting

Proper Baffles

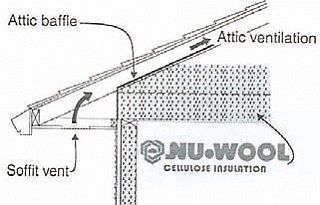

Attic insulation and proper soffit and roof venting are the most important items in the attic. The roof must have sufficient soffit and roof venting to allow cold outside air to enter in at the over hangs and soffits to be drawn up and out the roof venting systems.

-Note: Fiberglass blockers above the wall top plate, This keeps the soffits clear of cellulose insulation so that you can insulate to the maximum R-value

Venting

www.nuwool.com 1-800-748 -0128® 5/2009.

Attic Application Attics are dry-blown at a density not less than 1.6 pounds per cubic foot (pcf). The manufacturers’ coverage chart should be used for attic application. This insulation is applied with air during installation and will settle after it is applied. The manufacturers’ coverage chart has taken this settling factor in to account in calculating coverage. The chart has a column for installed thickness and a column for the thickness after settling. All of these calculations relate to desired R-values that the installer wants to achieve. Machines that produce more air during application, e.g., gas powered blowing machines, will often increase the volume of the insulation making it appear that adequate depth has been reached. The use of the manufacturers’ coverage chart is important to insure that regardless of application the end-user has the desired R-value. Installing bags rather than inches will achieve these results. Recessed lights can be covered with insulation as long as they are rated IC (insulation contact). With all other recessed lights insulation must be kept 3 inches away from the sides.

Keep insulation away from exhaust flues, space heaters, chimneys, water heaters and any other heat producing device. Refer to ASTM C-1015 for insulation guidelines. Insulation should not be blown into eave spaces where the ventilation will be restricted. Care should be taken that insulation is not blown in to “blind” areas that could fall into fireplace chases or other hazardous areas.

Examples of poor installation techniques. Attic Vent Baffles

- Vents are available for 16 and 24 inch spacing.

- Crease sides to fit and staple in-place every 12 inches.

- Foam baffles are bent to fit and natural pressure keeps them in-place.

- It is important to have enough eave baffle vents to equal the prescribed ventilation for the attic assuming a split between upper and lower ventilation.

- Insure that the baffle rests on the furthest point of the plate, the cold side. www.nuwool.com 1-800-748-0128